A flange bolt torque chart is essential for ensuring safety, preventing leaks, and maintaining structural integrity in industrial piping systems. Proper torque application, considering bolt size, material, and lubrication, ensures reliable connections. This guide provides comprehensive information on torque charts, their interpretation, and practical application.

Importance of Torque Charts

Torque charts are critical for ensuring proper bolt tightening in flange connections, preventing leaks, and maintaining structural integrity. They provide precise values to avoid under-tightening or over-tightening, which can lead to equipment failure or safety hazards. By following torque guidelines, engineers and technicians ensure reliable, long-lasting connections that meet industry standards like ASME B16.5 and EN 1591-1.

Purpose of the Guide

This guide provides a comprehensive overview of flange bolt torque charts, offering step-by-step instructions, practical insights, and expert recommendations. It aims to help users accurately interpret torque values, avoid common mistakes, and ensure compliance with industry standards for safe and efficient flange assembly. The guide is designed for engineers, technicians, and piping professionals seeking reliable torque application practices.

Understanding Flange Bolt Torque Charts

Flange bolt torque charts provide essential guidelines for proper bolt tightening, ensuring safety, preventing leaks, and maintaining structural integrity. They outline torque values based on bolt size, material, and lubrication for accurate application.

What is a Torque Chart?

A torque chart is a detailed guide providing specific torque values for flange bolts, ensuring proper tightening. It considers bolt size, material, and lubrication to prevent leaks and damage, crucial for maintaining piping system integrity and safety. These charts are often based on industry standards like ASME B16.5 and are used with calibrated torque wrenches for accurate application, though adjustments may be needed for real-world conditions.

Key Components of a Torque Chart

A torque chart typically includes bolt sizes, recommended torque values, lubrication factors, and tightening sequences. It provides essential data for accurate bolt tightening, ensuring safety and reliability. The chart often lists values for different bolt grades and materials, helping users determine the correct torque for specific applications, based on industry standards like ASME B16.5, to prevent over-tightening or under-tightening.

Factors Affecting Torque Values

Torque values are influenced by bolt size, material, friction, lubrication, and gasket type. These factors determine the required force to ensure a secure, leak-free connection without over-tightening.

Bolt Size and Type

Bolt size and type significantly influence torque values. Larger bolts require higher torque due to increased diameter and load-bearing capacity. Material strength, such as ASTM A193 B7, also affects torque requirements. The friction coefficient varies with bolt type, impacting the applied torque. Proper bolt selection ensures safe and reliable connections, while incorrect choices can lead to failure or leakage. Always use torque charts specific to bolt size and type for accurate results.

Material and Coatings

Material and coatings significantly impact torque values. Different materials, such as stainless steel or carbon steel, have varying strength properties, affecting the required torque; Coatings like PTFE or zinc plating reduce friction, altering torque requirements. Always consult torque charts specific to the material and coating to ensure proper tightening, preventing over-tightening or under-tightening, which can lead to leakage or bolt failure for optimal safety and reliability.

Friction and Lubrication

Friction and lubrication significantly influence torque values. Proper lubrication of bolts and nuts is crucial for achieving accurate torque application. Using lubricants reduces friction, ensuring the correct axial load is applied. Always follow recommended lubrication practices, such as applying engine oil to threads and washers, to avoid over-tightening or under-tightening, which can lead to leaks or bolt damage.

Gasket Type

The gasket type plays a critical role in determining torque values. Different materials, such as ASME-standard gaskets, require specific torque recommendations to ensure a proper seal. The torque values provided in charts are typically based on ideal conditions, including new, well-lubricated bolts and the specified gasket type. Ensure compatibility between gasket material and flange to maintain safety and prevent leaks.

Using Torque Charts in Practice

Referencing torque charts ensures accurate bolt tightening, promoting safety and efficiency. Use calibrated tools, apply lubrication as specified, and follow proper tightening sequences to achieve optimal results.

Step-by-Step Guide

Select the correct torque chart for your flange size and class. 2. Identify bolt size, material, and lubrication type. 3. Apply recommended torque in sequence, tightening bolts evenly to avoid uneven stress. 4. Verify all bolts meet specified torque values. 5. Recheck torque after assembly to ensure accuracy and reliability in the connection.

Common Challenges

Incorrect torque wrench calibration, uneven bolt tightening, and ignoring lubrication factors are frequent issues. Environmental conditions and material variability can affect torque accuracy. Over-tightening risks bolt damage, while under-tightening may lead to leaks. Ensuring proper sequencing and verifying torque post-assembly are critical to avoid common pitfalls and ensure reliable connections in industrial applications.

Sources of Torque Charts

ASME B16.5 and EN 1591-1 provide standardized torque charts. Online tools like Flange Bolt Chart and apps offer quick access to accurate torque values and sequences.

ASME Standards

ASME B16.5 provides detailed torque charts for pipe flanges, covering classes from 150 to 2500. These standards ensure consistency and safety in bolting practices. They include tables for bolt sizes, torque values, and wrench sizes, facilitating accurate calculations. Compliance with ASME standards is crucial for reliable and secure flange connections in industrial applications.

Online Tools and Apps

Online tools like Flange Bolt Chart offer instant access to bolt sizes and torque patterns. These apps provide ASME-compliant data, enabling quick lookups for flange bolt specifications. With offline functionality, they are ideal for fieldwork, ensuring accurate and efficient torque calculations. They simplify complex data, making it accessible for pipefitters and engineers, and reduce errors compared to manual chart searches.

How to Read a Torque Chart

Understand the layout, identify torque values for specific bolts, and apply lubrication factors. Match bolt size and class with recommended torque, ensuring accuracy for safe and reliable connections.

Interpreting Data

Interpreting flange bolt torque charts involves identifying the correct torque values based on bolt size, class, and material. Locate the specific bolt type and corresponding torque value, considering lubrication factors to ensure accurate application. Cross-reference with ASME standards and manufacturer guidelines to verify data accuracy and compliance, ensuring safe and reliable connections.

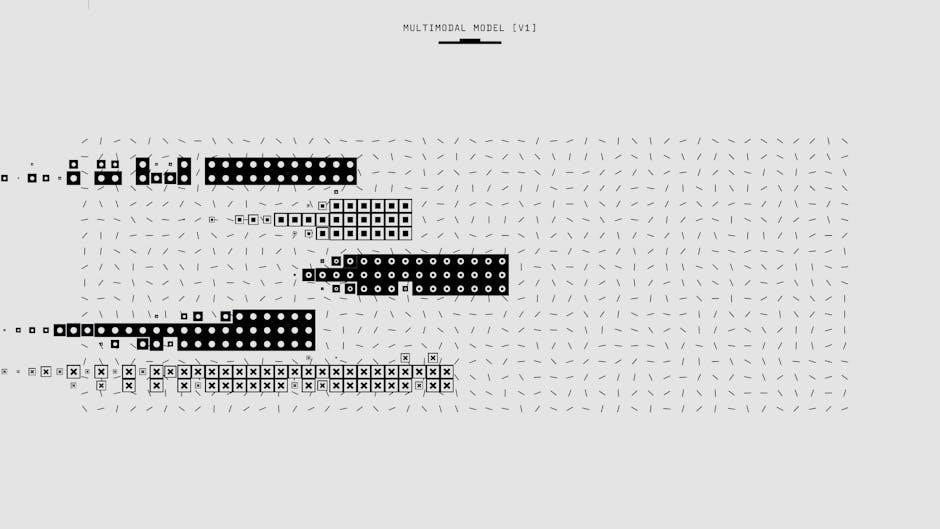

Typical Layout

A typical flange bolt torque chart is organized in a table format, listing bolt sizes, classes, and corresponding torque values. Columns often include bolt diameter, thread pitch, and recommended torque ranges. Additional details like wrench sizes and torque sequences may be included. The layout is standardized, ensuring users can quickly locate and apply the correct specifications for their specific flange assembly needs.

Calculating Bolt Torque

Calculating bolt torque involves understanding bolt size, material, and lubrication factors. Proper torque application ensures structural integrity and leak prevention in industrial applications, using calibrated tools for accuracy.

Formula and Variables

The bolt torque formula, T = K * D * P, calculates the required torque, where T is torque, K is the nut factor, D is the bolt diameter, and P is the desired bolt tension. Variables like bolt size, material, and friction factor significantly impact torque values, ensuring precise calculations for safe and reliable industrial applications.

Applied Torque Calculation

Applied torque is calculated using the formula T = K * D * P, where T is torque, K is the nut factor, D is the bolt diameter, and P is the desired bolt tension. This calculation ensures the correct force is applied, preventing under-tightening or over-tightening, which can lead to leaks or damage. Proper lubrication and accurate measurements are crucial for reliable results.

Importance of Proper Torque

Proper torque ensures flange connections are secure, preventing leaks and maintaining structural integrity. It guarantees even gasket compression and avoids damage from under- or over-tightening, enhancing safety and reliability.

Safety and Reliability

Proper torque ensures flange connections are secure, preventing catastrophic failures. It maintains structural integrity, avoids gasket damage, and reduces the risk of leaks or joint separation. Correct torque application enhances safety by preventing sudden system failures and ensures reliable operation over time. Adhering to torque guidelines minimizes risks to personnel and equipment, making it a critical factor in industrial piping systems.

Preventing Leaks

Proper torque application ensures even gasket compression, preventing leaks. Under-tightening can lead to gaps, while over-tightening may damage the gasket or flange. Using correct torque values and lubrication ensures a leak-free seal. Adhering to torque charts and sequences is critical for maintaining joint integrity and preventing fluid leakage in industrial piping systems.

Common Mistakes to Avoid

- Over-tightening bolts can damage threads or gaskets.

- Using incorrect tools may lead to improper torque application.

- Ignoring lubrication can result in inaccurate torque values.

- Not following the recommended tightening sequence causes uneven stress.

Over-Tightening

Over-tightening bolts can lead to thread damage, gasket failure, or flange deformation. Always use calibrated tools and adhere to torque chart guidelines to avoid exceeding maximum recommended values. Excessive force may compromise the integrity of the connection, leading to leaks or equipment damage. Proper lubrication and sequence are critical to prevent this common error.

Using Wrong Tools

Using incorrect tools, such as uncalibrated torque wrenches, can result in improper bolt tension, leading to under- or over-tightening. This may cause gasket damage, bolt stripping, or flange warping. Always use tools specified in torque charts to ensure accurate torque application and prevent potential failures. Proper equipment is essential for maintaining safety and reliability in flange assemblies.

Tools and Equipment Needed

Torque wrenches, lubricants, and calibrated tools are essential for accurate bolt tightening. Proper equipment ensures safety and reliability in flange assemblies. Use high-quality tools to achieve precise torque values.

Torque Wrenches

Torque wrenches are critical for applying precise force to flange bolts. Both manual and hydraulic wrenches are used, depending on the application. Ensure wrenches are calibrated regularly to maintain accuracy. Proper tool maintenance prevents wear and tear, guaranteeing consistent torque application. Using the correct wrench size and type is essential for safety and reliability in flange assembly operations.

Lubricants

Lubricants play a crucial role in flange bolt torque applications by reducing friction and preventing corrosion. Properly lubricated bolts ensure accurate torque values and even stress distribution. Common lubricants include oil and grease, with specific types recommended for different materials; Applying the correct lubricant ensures optimal gasket sealing and prevents over-tightening, which can damage bolts or flanges.

Industry Standards and Compliance

Adhering to ASME B16.5 and EN 1591-1 standards ensures compliance and safety in flange bolt torque applications, guaranteeing reliability and preventing leaks through accurate torque specifications and proper procedures.

ASME B16.5

ASME B16.5 provides standardized dimensions, tolerances, and torque values for pipe flanges and flanged fittings. It covers classes from 150 to 2500, ensuring consistency and safety in bolt torque applications. The standard includes templates for drilling and wrench sizes, essential for accurate flange assembly and compliance with industry regulations. Proper adherence ensures reliable and leak-free connections in piping systems.

EN 1591-1

EN 1591-1 outlines European standards for flange connections, providing guidelines for bolt torque calculations. It emphasizes proper tightening sequences and verifies joint integrity. The standard ensures compliance with safety and reliability requirements, particularly for industrial piping systems. Adherence to EN 1591-1 is crucial for maintaining structural integrity and preventing leaks in flanged joints across various industries.

Case Studies and Examples

Real-world applications demonstrate the effectiveness of torque charts in ensuring safe and reliable flange connections. Lessons learned from refinery and offshore projects highlight best practices in torque management.

Real-World Applications

Torque charts are crucial in industries like oil refineries, offshore platforms, and chemical plants. For instance, in refinery piping systems, accurate bolt torque ensures leak-free connections, preventing hazardous leaks. Offshore platforms rely on these charts to secure flanges under harsh marine conditions. Similarly, chemical plants use torque charts to maintain equipment integrity and safety during high-pressure operations, ensuring reliability and compliance with industry standards.

Lessons Learned

Experienced technicians emphasize adhering strictly to torque charts to avoid over-tightening, which can damage flanges or bolts. Proper lubrication and using calibrated tools are critical. Real-world applications highlight that ignoring friction factors or gasket types can lead to leaks or equipment failure. Following established guidelines ensures safety, efficiency, and compliance with industry standards, minimizing downtime and costly repairs in industrial operations.

Troubleshooting Torque Issues

Common issues include over-tightening, under-tightening, and incorrect lubrication. Check bolt condition, verify torque wrench calibration, and ensure flange alignment. Refer to torque charts for accurate specifications.

Diagnosing Problems

Common issues include over-tightening, under-tightening, and incorrect lubrication. Check for bolt damage, flange warping, or leaks. Verify torque wrench accuracy and flange alignment. Inspect bolts for rust or wear. Ensure proper lubrication and consult torque charts for specifications. Addressing these factors helps identify root causes and prevents recurring issues in flange bolt connections.

Resolving Common Issues

Address over-tightening by loosening bolts and re-torquing sequentially. For under-tightening, reapply torque in stages. Replace damaged or corroded bolts immediately. Ensure flanges are clean and aligned properly. Use recommended lubricants and verify torque wrench calibration. Referencing torque charts ensures accurate adjustments, preventing future issues and maintaining system integrity effectively.

Best Practices for Torque Application

Always follow manufacturer guidelines for torque values and sequences. Use calibrated tools and ensure bolts are properly lubricated. Apply torque in a star pattern to maintain even stress distribution and prevent gasket damage, ensuring a leak-free and secure connection.

Sequencing and Patterns

Proper bolt sequencing ensures even stress distribution, preventing gasket damage. Use a star pattern, tightening bolts in a circular sequence, numbered clockwise or counterclockwise. Always follow ASME guidelines or torque charts for specific patterns. Ensure bolts are evenly torqued in multiple passes, starting with hand tightening. Verify the sequence with torque charts or apps for accuracy and reliability in flange connections.

Verification

Verification ensures all bolts are tightened to the correct torque, maintaining safety and reliability. Use calibrated torque wrenches to confirm values from the chart. Cross-reference bolt specs with ASME guidelines to ensure accuracy. Double-check lubrication and friction factors, as these directly affect torque application. Document all readings for future inspections and compliance. Proper verification prevents over-tightening and ensures a leak-free connection, adhering to industry standards and best practices.

Future Trends in Bolt Torque Technology

Advancements include smart torque wrenches, AI-driven calculators, and software integration for precise bolt tightening. These tools enhance accuracy, efficiency, and compliance with evolving industry standards like ASME B16.5 and EN 1591-1.

Advances in Tools

Modern tools like digital torque wrenches and software integration are revolutionizing bolt torque technology. Apps such as Flange Bolt provide instant access to torque charts, wrench sizes, and sequences. These tools enhance accuracy, reduce errors, and streamline the tightening process. They also ensure compliance with standards like ASME B16.5 and EN 1591-1, making operations safer and more efficient.

Software Integration

Software integration enhances the use of flange bolt torque charts by enabling real-time data access and precise calculations. Tools like Flange Bolt Chart offer offline functionality, ensuring instant lookups of bolt sizes, torque sequences, and wrench sizes. This integration streamlines workflows, improves reporting, and ensures compliance with industry standards, making it a vital component of modern piping operations and maintenance activities.

Flange bolt torque charts are crucial for ensuring safe and reliable connections, preventing leaks, and maintaining structural integrity. Proper torque application, guided by charts, enhances system performance and longevity, while adhering to industry standards ensures optimal results and minimizes risks in industrial operations.

Flange bolt torque charts provide essential guidelines for proper bolt tightening, ensuring safety, preventing leaks, and maintaining structural integrity. Key factors include bolt size, material, lubrication, and friction. Adhering to industry standards like ASME B16.5 and EN 1591-1 is crucial for accurate torque calculations. Proper sequencing and verification ensure reliable connections, minimizing risks in industrial piping systems and enhancing overall system performance and longevity.

Final Recommendations

Always refer to flange bolt torque charts for precise values, ensuring safety and reliability. Use calibrated tools like torque wrenches and follow ASME B16.5 standards. Apply proper lubrication, verify bolt sizes, and adhere to tightening sequences. Double-check calculations and consult industry guidelines for specific applications to avoid over-tightening and ensure leak-free connections in piping systems;